Choosing the Right Diamond Blade for Optimal Cutting Performance

Introduction:

When it comes to diamond blades, selecting the right one for your cutting application is crucial for achieving optimal performance and longevity. This guide aims to provide insights into choosing the most suitable diamond blade for different applications, ensuring that your cutting tasks are efficient and effective.

1. Understanding Diamond Blade Basics:

a. Blade Types:

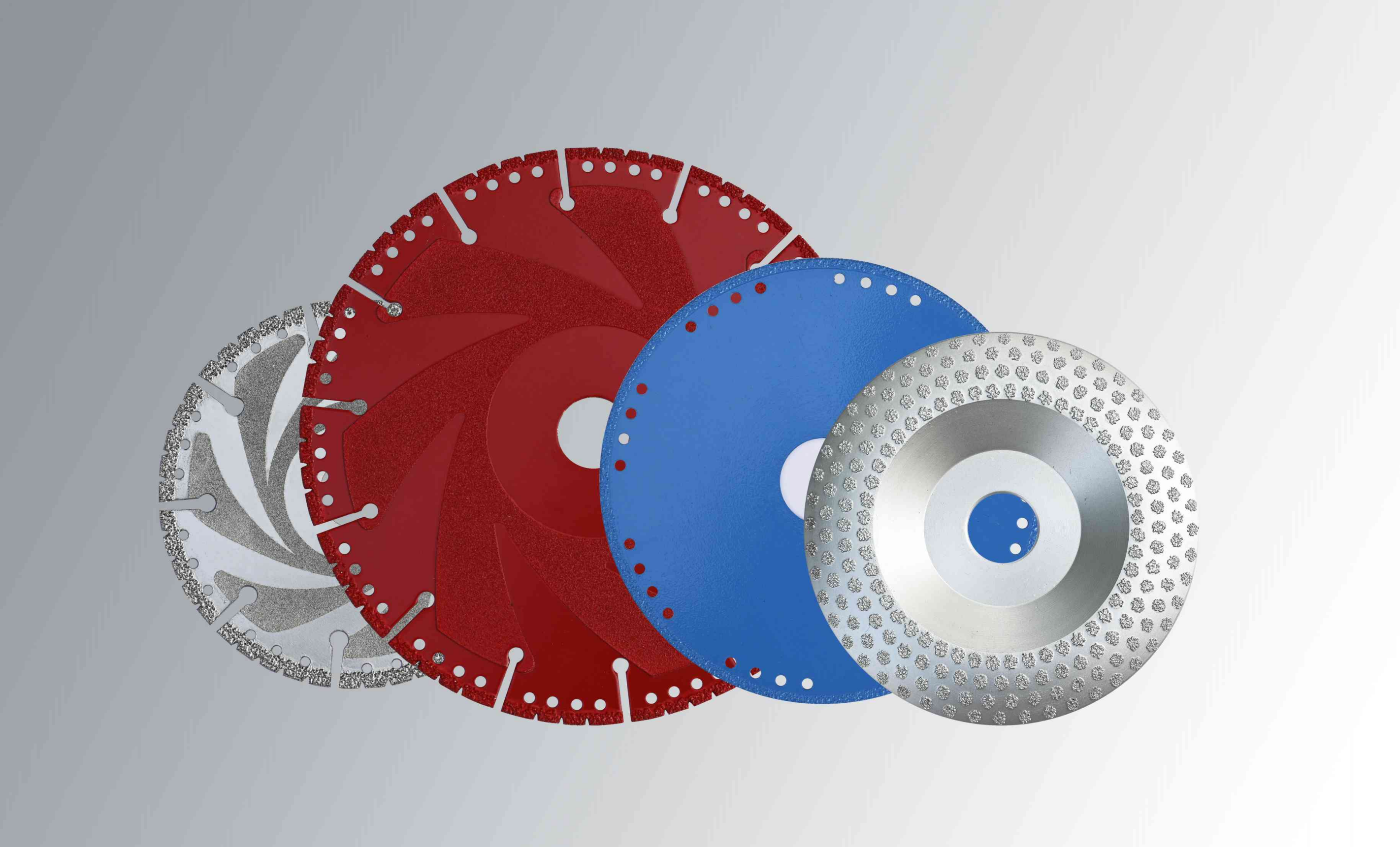

- Segmented Blades: Ideal for general-purpose cutting, these blades are versatile and suitable for a wide range of materials.

- Continuous Rim Blades: Designed for precision cutting, they offer smooth, chip-free results, making them ideal for delicate materials like tiles and ceramics.

- Turbo Blades: Combining the benefits of both segmented and continuous rim blades, turbo blades offer faster cutting speeds and improved cooling, making them suitable for various applications.

b. Diamond Grit and Bond:

- Grit Size: Coarse grit for softer materials, fine grit for harder materials.

- Bond Types: Soft bonds for hard materials, hard bonds for soft materials.

2. Matching Blades to Materials:

a. Concrete Cutting:

- Recommended Blade: Segmented blade with a hard bond.

- Why: The hard bond ensures durability when cutting through the abrasive nature of concrete.

b. Asphalt Cutting:

- Recommended Blade: Segmented blade with undercut protection.

- Why: Undercut protection helps prevent blade damage when cutting through abrasive materials like asphalt.

c. Tile and Stone Cutting:

- Recommended Blade: Continuous rim blade with fine grit.

- Why: The continuous rim provides a clean cut, and fine grit is suitable for delicate materials like tiles and natural stone.

3. Tips for Extended Blade Life:

a. Proper Blade Cooling:

- Ensure proper water flow: Especially crucial when cutting harder materials to prevent overheating.

b. Optimal Cutting Speed:

- Do not force the blade: Let the blade do the work at the recommended speed to avoid premature wear.

c. Regular Blade Inspection:

- Check for wear and damage: Replace blades when they show signs of wear or damage to maintain cutting precision.

Conclusion:

Choosing the right diamond blade is an essential aspect of achieving efficiency and precision in your cutting applications. By understanding the basics of blade types, diamond grit, and bonding, as well as matching blades to specific materials, you can ensure that your diamond blades deliver optimal performance and longevity.

Remember, each cutting task is unique, and selecting the appropriate diamond blade will not only enhance your productivity but also contribute to the overall success of your projects.